- Safety refresher

- Sequence mapping

- Half split technique

- Six-point technique

- Five whys

- Flow charts.

- Preventive maintenance

- Condition based monitoring.

- Fault recording

Upon completion of this course, the learner will:

- Complete a safety refresher to ensure safety is at the forefront of all they do.

- Understand how to produce a sequence map to understand the system so they can quickly identify problems and understand the cause.

- Will know how to use the following fault-finding techniques, half split, six-point and five whys.

- Will be able to use and create fault-finding aids such as flow charts.

- Be able to create a preventive maintenance strategy taking into account manufacturer guidance and historical failure data.

- Understand the importance of maintaining equipment to fulfil PUWER regulations.

- Understand what we mean by condition-based monitoring and be able to apply a variety of techniques.

- Be able to effectively record equipment failure and understand how to use data when fault finding and its importance when creating preventative maintenance strategies.

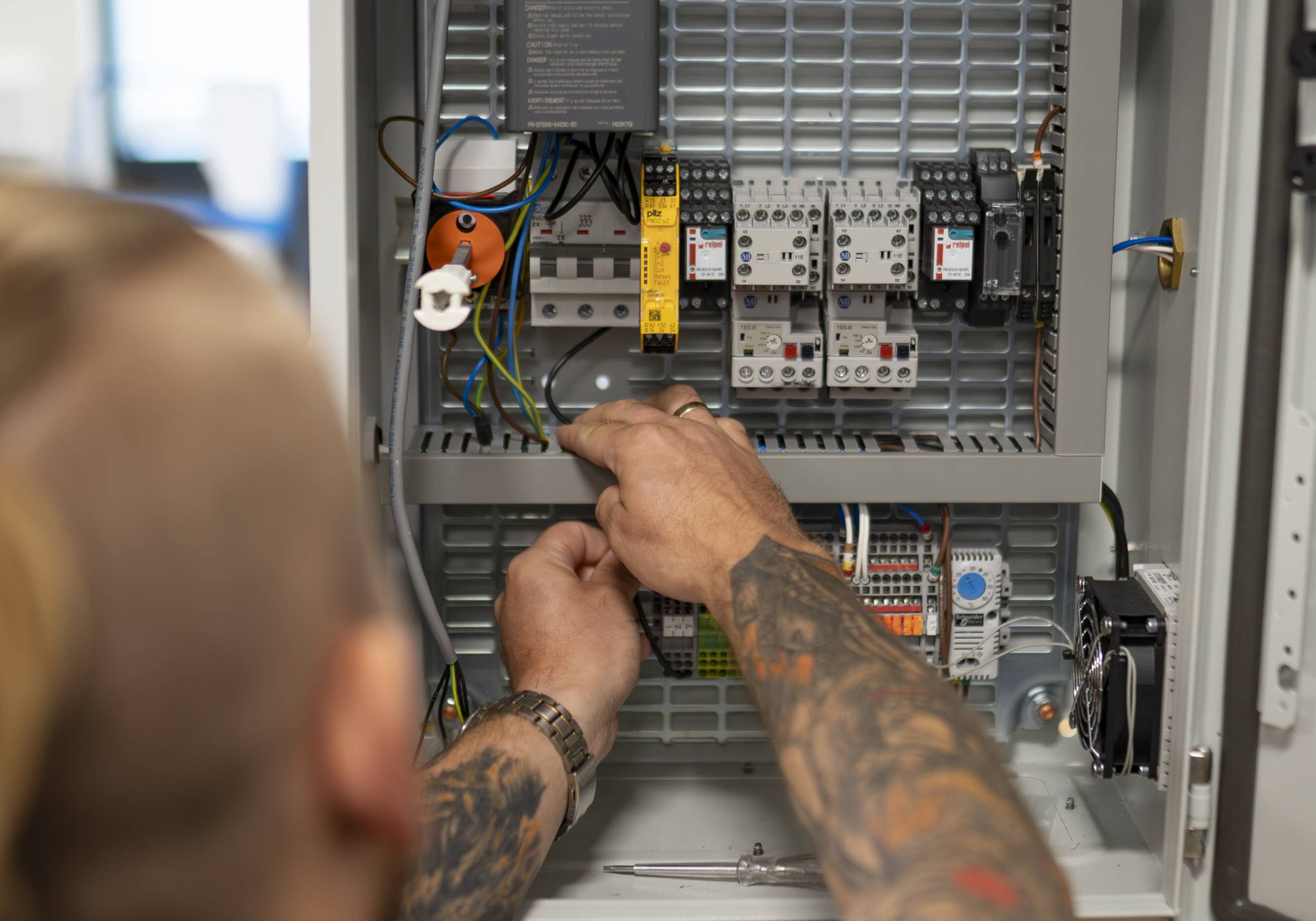

- Maintenance engineers

- Electrical engineers

- Mechanical fitters

- Service engineers

- Maintenance managers

- Controls engineers

- Automation engineers

- System Integrators